Anthony Davidson, who works as a simulator pilot at Mercedes, visited the production site at the team’s base in Brackley, where he learned about the manufacturing process of complex metal alloy parts. And he was joined on this tour by James Peddle, a machine workshop engineer.

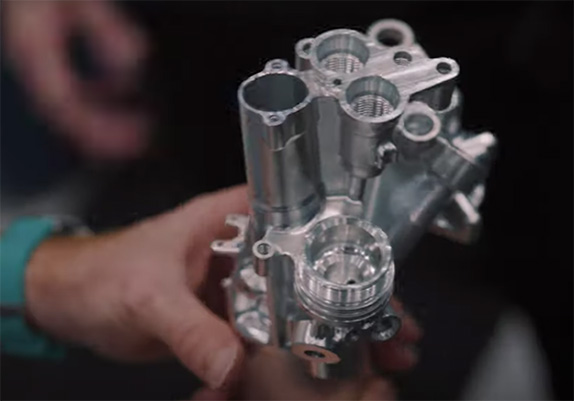

Anthony Davidson: So, James, we’re in the machine shop office and we’re watching everything from here. But before we get down, I’d like you to tell me how this titanium billet turns into a front axle that looks so impressive?

James Paddle: Designers worked on this part for a long time and then we get the drawings. And the first thing we need to do is to order such a titanium rod. It weighs about 35 kg and we start processing it on machines, then it takes the shape of the desired part.

Anthony Davidson: Why titanium? Why can’t steel or another material be used?

James Paddle: We could make the thru axle out of steel, but it would weigh more. With titanium, we can get a part that weighs much less for the same size.

Anthony Davidson: How early do you have to start work so that such a part arrives on the machine on time?

James Paddle: Sometimes we start production of a part even before the designers have completed development.

Anthony Davidson: So we put on goggles, now we can go to the store. Tell me what’s going on here?

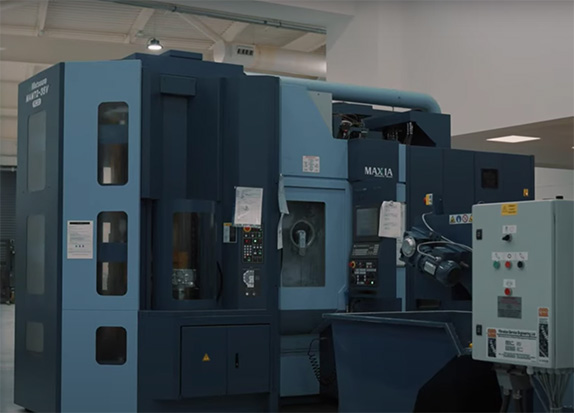

James Paddle: Welcome to the machine factory, here you can see 24 machines; Of these, 13 are 5-axis machining centers that produce parts of the strangest and most interesting shapes.

For example, there is now a five-axis milling of the workpiece. The display shows lines of code that follow each other in quick succession and you can see that the tools in the spindle also rotate very quickly. But the part itself also rotates, which makes it possible to realize the most complex geometry.

Anthony Davidson: What kind of white liquid flows out of there?

James Paddle: We use a special coolant that consists of 97% water and 3% oil. It serves to lubricate the cutter and helps to reduce the temperature during the machining process. This also contributes to the most efficient operation of the cutter.

Anthony Davidson: Is there a production of such a part like this now?

James Paddle: Yes, now the machine performs just such a task.

Anthony Davidson: These 5-axis machining centers can produce parts of the most bizarre shapes, simply amazing! Real works of art are created here!

Source: F1 News

I am Christopher Clyde, an experienced journalist and content writer with a passion for sports. I have been writing about Formula 1 news for the past five years and am currently employed as an author at athletistic.com, one of the top sports websites in the US.